The Unexpected Hidden Cost of Cheap Membrane Switches:

You may think that a well-established technology always saves money, but cheap membrane switches may not be all they are cracked up to be. They often fail to deliver the savings you hoped for in larger projects. It’s frustrating when a seemingly cost-effective component leads to unexpected problems down the line, isn’t it?

“Tired of components that let you down? At RH, we make sure quality isn’t an afterthought. We’re experts at spotting and preventing common issues, so your products always perform reliably.” – Mike Walker – Business Development Manager

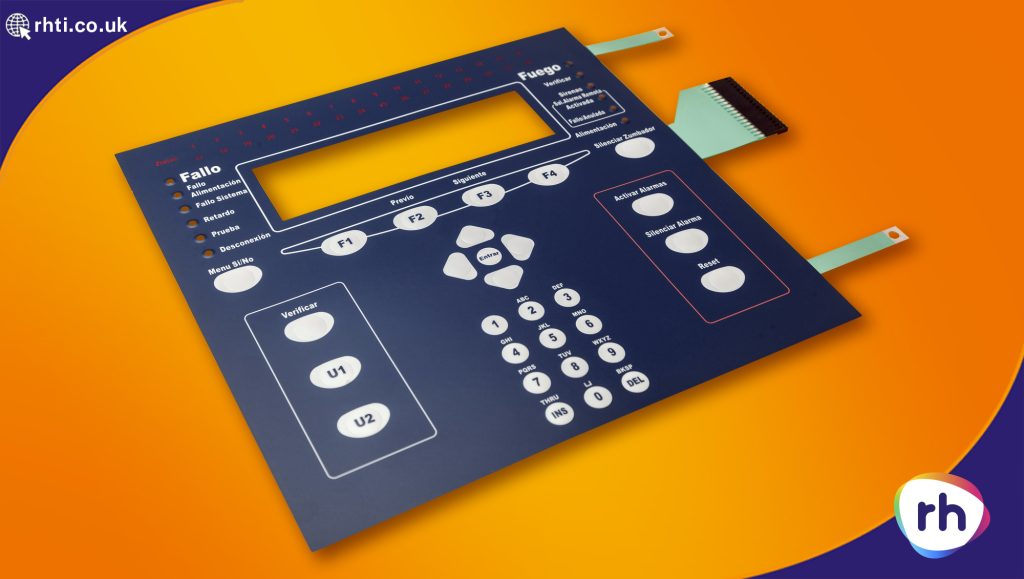

In the world of customer-centric design, understanding potential failure points is crucial for delivering reliable products and maintaining a strong brand reputation. Many companies cut corners on membrane switch quality, leading to significant long-term expenses, customer dissatisfaction, and even costly recalls. At RH Technical Industries, our extensive experience in membrane switch manufacturing is specifically engineered to prevent common and expensive issues. We delve into challenges like silver migration, ESD, seal integrity, and material incompatibility. These issues illustrate how our meticulous approach ensures product functionality and superior user experience from the outset.

Why Quality Matters: Common Challenges and Potential Failure Points

While membrane switches are often chosen for their cost-effectiveness and compact design, opting for basic or poorly manufactured versions can introduce significant vulnerabilities. For instance, single-sided membrane switches, though inexpensive to produce, possess inherent weaknesses that frequently lead to circuitry failure, making them unsuitable for high-performance applications. The perception that membrane switches are simply low-cost components can lead to decisions that introduce substantial long-term expenses in the form of recalls and damage to brand reputation. This highlights a critical tension: true cost-effectiveness is derived from reliability and appropriate design for the application, not merely the lowest upfront price. Common causes of membrane switch failure, often rooted in product design and manufacturing process control rather than user error, include:

Issues with Cheap Membrane Switches:

- Silver Migration: Cross-over connections, where silver circuit traces are placed over one another with only a thin dielectric layer for separation, are highly susceptible to silver migration in high humidity conditions. This phenomenon can cause electrical shorts, compromising functionality.

Simple Solution: Use carbon or multi-layer insulation between traces or implement a non-crossover circuit design using ‘thru-hole’ technology.

- Electrostatic Discharge (ESD): Insufficient perimeter around the active switch area leaves membrane switches vulnerable to electrostatic discharge, which can damage circuitry and lead to assembly malfunction.

Simple Solution: Increase the dielectric perimeter around the active switch area or integrate ESD shielding layers.

- Seal Integrity: An Inadequate gasketing area can severely limit the switch’s ability to protect against water, moisture, and chemical ingress. This makes it challenging, if not impossible, to achieve the necessary hermetic seal for reliable operation in harsh environments, leading to premature failure.

Simple Solution: Employ high-quality, adhesives in the construction suitable for the application & materials to be bonded and ensure adequate gasketing area and proper bonding techniques.

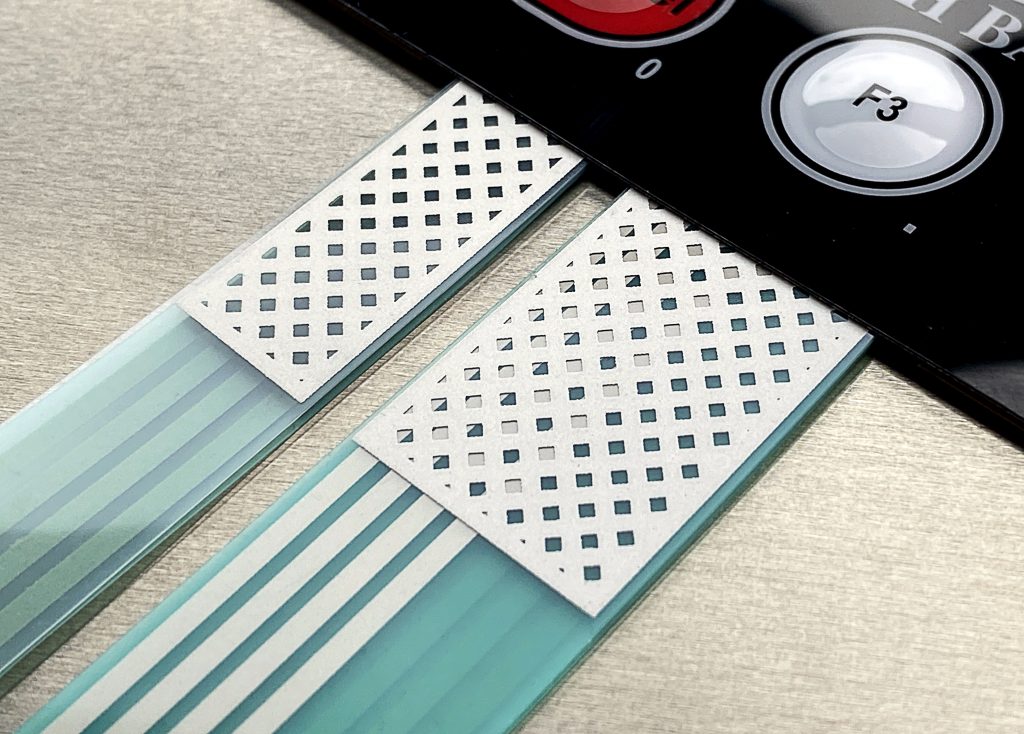

- Tail Fracture: The flexible tail that connects the switch to the control unit is a common point of failure. Poorly designed or elongated tail exits can lead to creasing or bending near the exit point. This intensifies the risk of stress fractures.

Simple Solution: Design with robust, reinforced tail exits and optimise cable routing to minimise stress points.

- Delamination: Stress between the tails and the main switch body can cause the pressure-sensitive adhesive (PSA) to shear over time. Once delamination begins, the environmental seal is compromised, exposing the internal circuitry to contaminants and leading to failure.

Simple Solution: Use high-performance, shear-resistant PSAs and ensure proper adhesion and strain relief where the tail meets the main body.

- Material Incompatibility: Using unsuitable materials for the application can lead to rapid degradation. For example, polycarbonate overlays are only suitable for low-frequency devices; their use in high-actuation applications often results in cracking, exposing the underlying circuitry. Similarly, polyester domes, ideal for room temperature, can crack in cold conditions or flatten in heat, causing erroneous activations.

Simple Solution: Select materials specifically engineered for the application’s frequency of use, environmental conditions (temperature, humidity), and chemical exposure.

- Adhesive Mismatch: The selection of cheaper pressure-sensitive adhesives (PSAs) can lead to incompatibility with the application environment, surface energy, inks, or other assembly materials, resulting in adhesive failure and compromised integrity.

Simple Solution: Conduct thorough material compatibility testing and select PSAs formulated for the specific application environment and interacting surfaces.

Quality Manufacturing from RH

These potential failure points underscore the importance of meticulous design and manufacturing processes. RH Technical Industries, by prioritising quality throughout every step of production and offering comprehensive customisation with robust engineering functionality, aims to guide clients away from these hidden costs, emphasising that true long-term value stems from reliability and an application-appropriate design. Not every solution is simple, but we have years of experience to always find a quality solution! Contact RH today about your next project and place your manufacturing in safe hands!