Our Integrated Finishing Capabilities

We utilise industry-leading finishing processes to ensure all components, labels, and graphic overlays meet the highest standards for dimensional accuracy, application, and durability.

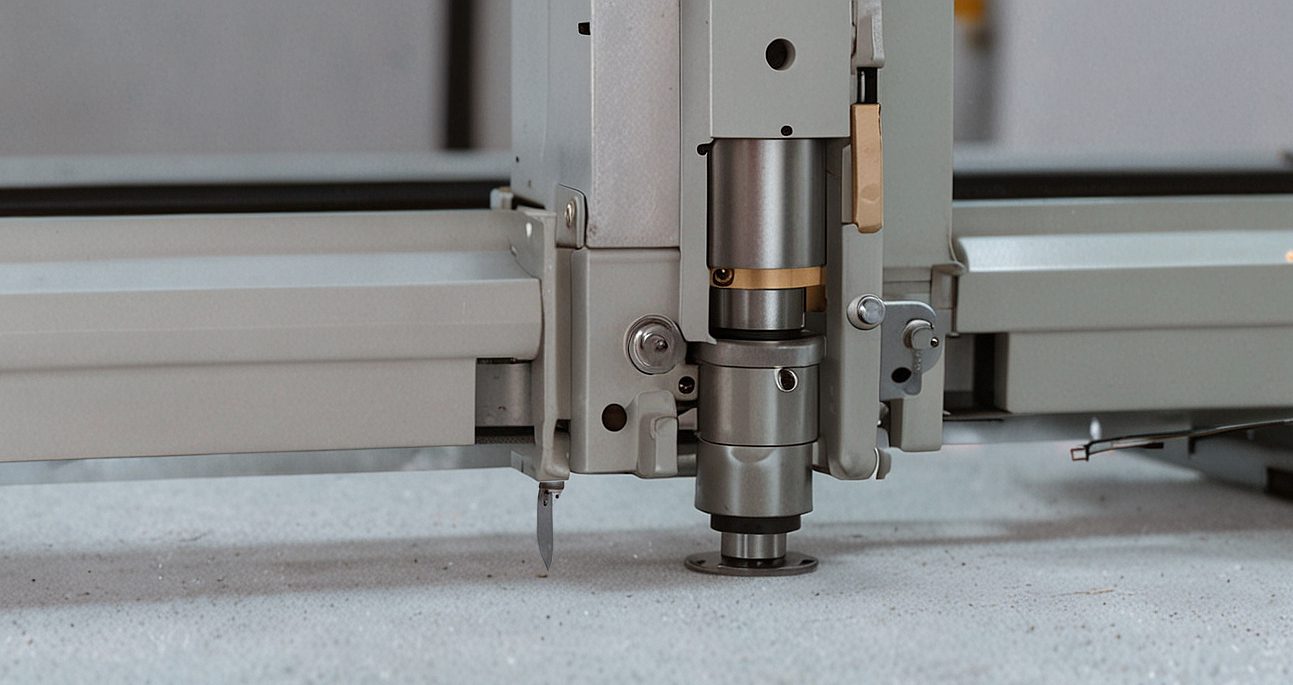

Digital Cutting

Utilising advanced digital systems for clean, accurate, and versatile component separation without physical dies.

- Tooling-Free & Cost-Effective: Eliminates setup costs and time associated with traditional tooling.

- Ideal for Prototypes & Low Volume: Enables rapid iteration, design testing, and short-run production.

- Complex Geometries: Perfectly executes highly intricate and custom shapes with fine detail.

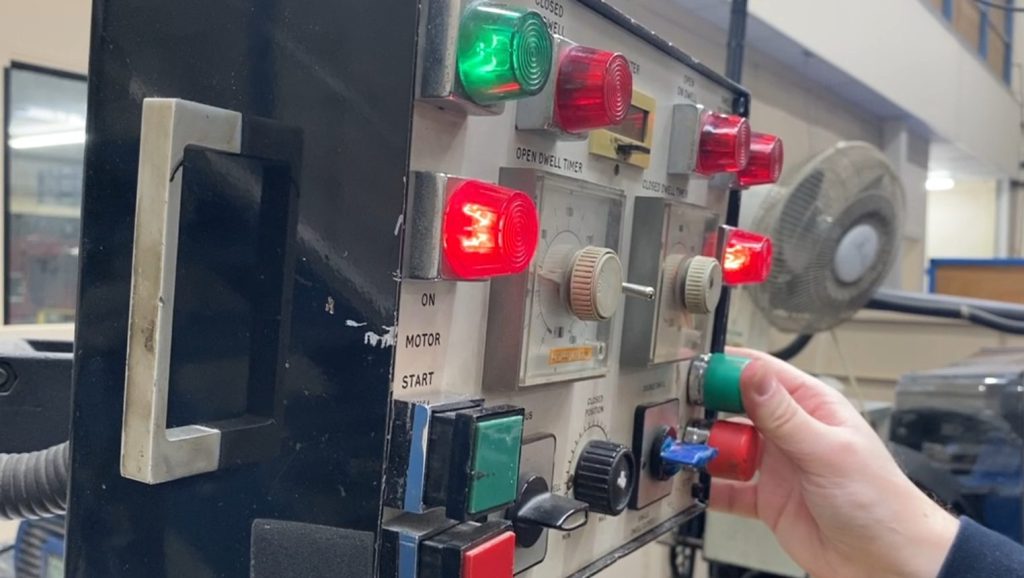

Preco Tooling & Crosland Die Cutting

We offer both durable steel-tooled dies (Preco) and platen dies cutting (Crosland) for the most efficient and precise material conversion at scale.

- High-Volume Efficiency: Delivers consistent, repeatable results for large production runs with fast cycling times.

- Tight Tolerance Accuracy: Guarantees precise registration and component dimensions, especially when paired with printed graphics.

- Material Versatility: Suitable for kiss-cutting and through-cutting plastics, heavy-duty adhesives, foams, and foils.

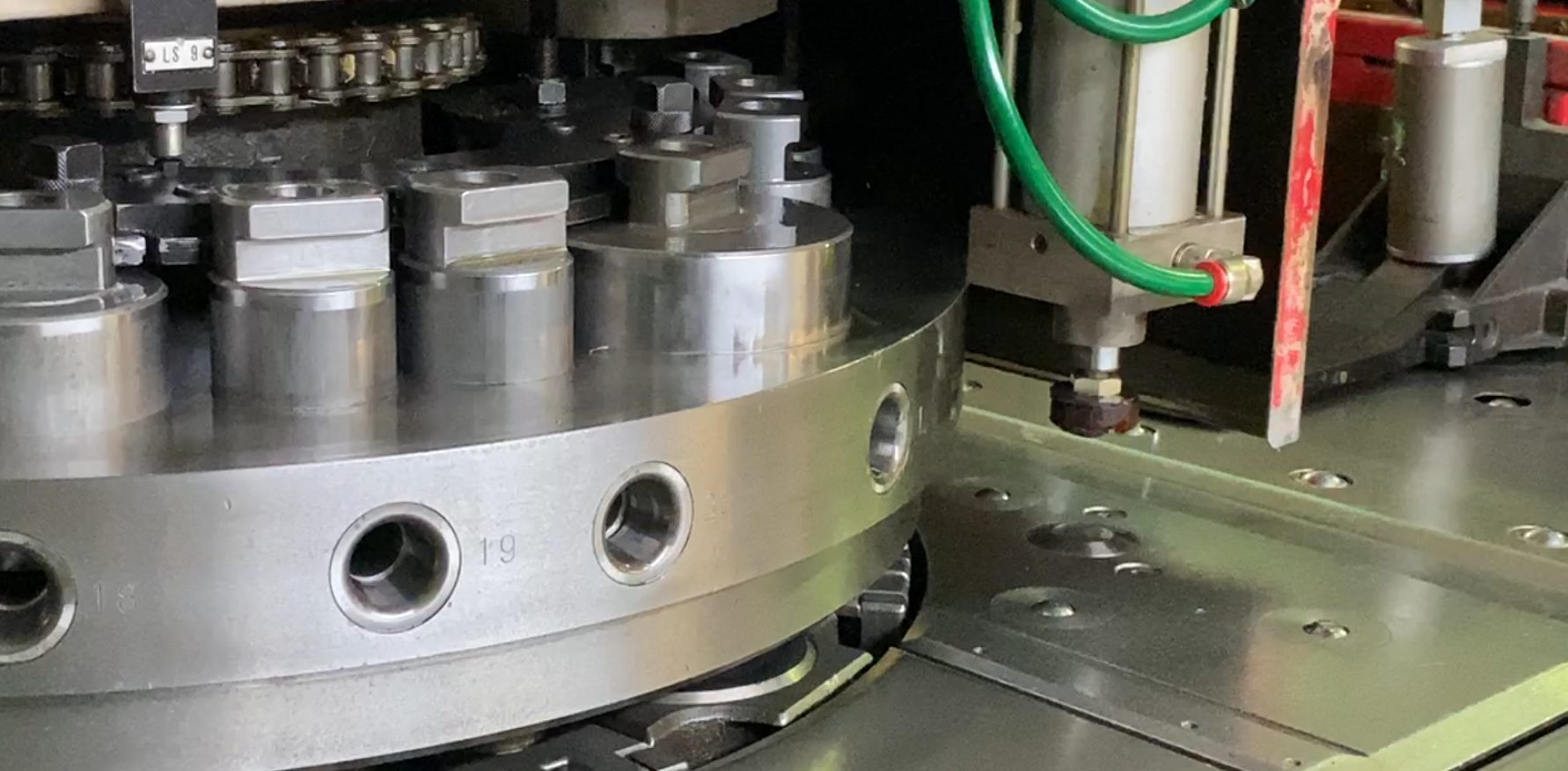

CNC Punching

A robust and reliable method for rapidly punching holes, cutouts, and simple shapes into panels and components.

- Speed and Consistency: Quick, repeatable execution for standard features across large quantities of parts.

- Multi-Layer Processing: Capable of handling thicker or more rigid materials that may challenge other cutting methods.

- Standard Feature Integration: Ideal for creating precise holes for switches, display windows, and panel mounts.

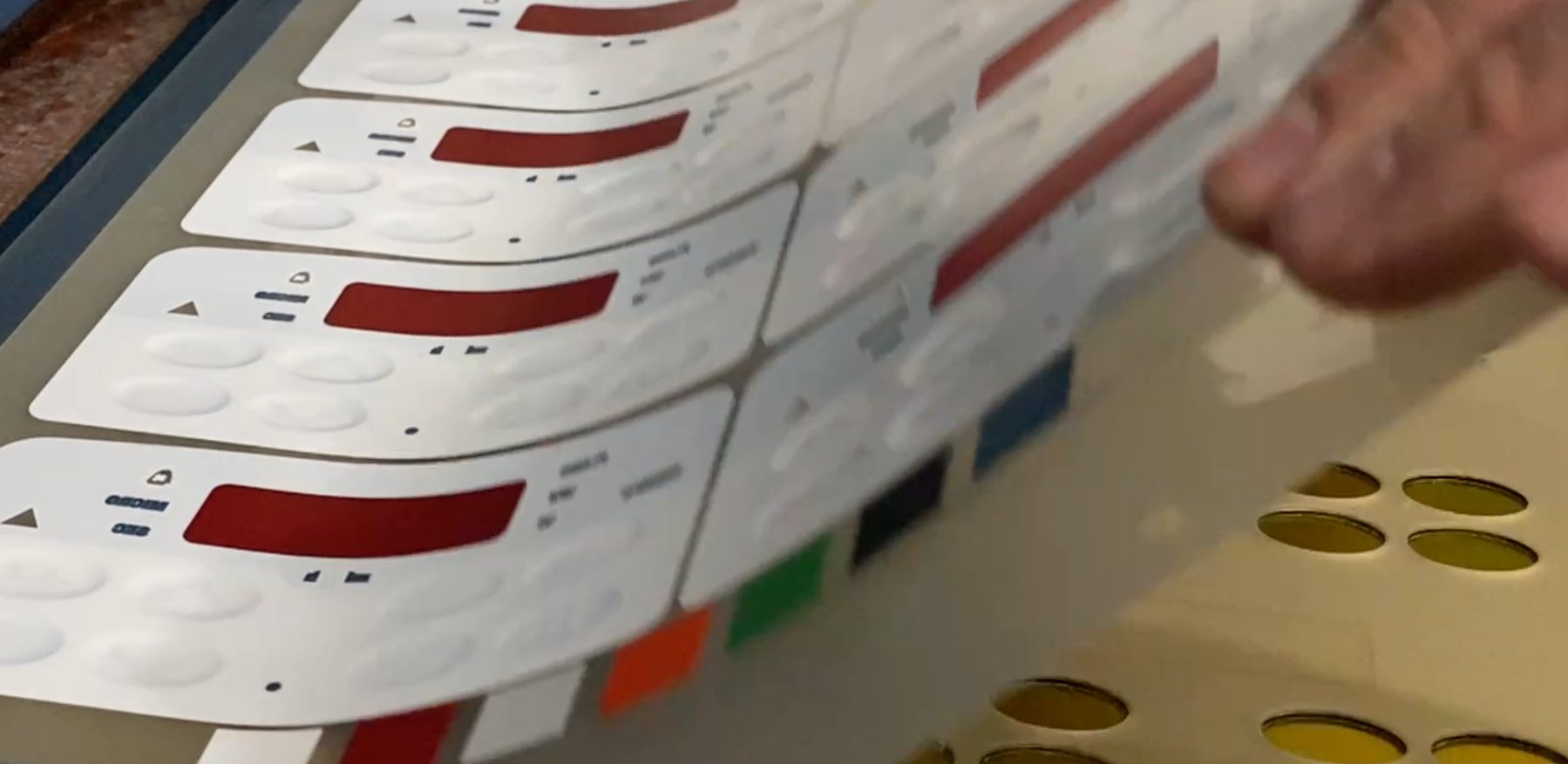

Embossing

Enhance the tactile experience and functionality of your graphic overlays and keypads with professional embossing.

- Tactile Feedback: Creates raised features (e.g., domes or rings) for key actuation and user interaction.

- Increased Durability: Reinforces critical areas of the overlay, improving lifespan and feel.

- Professional Finish: Adds a high-end, functional aesthetic that differentiates your product.

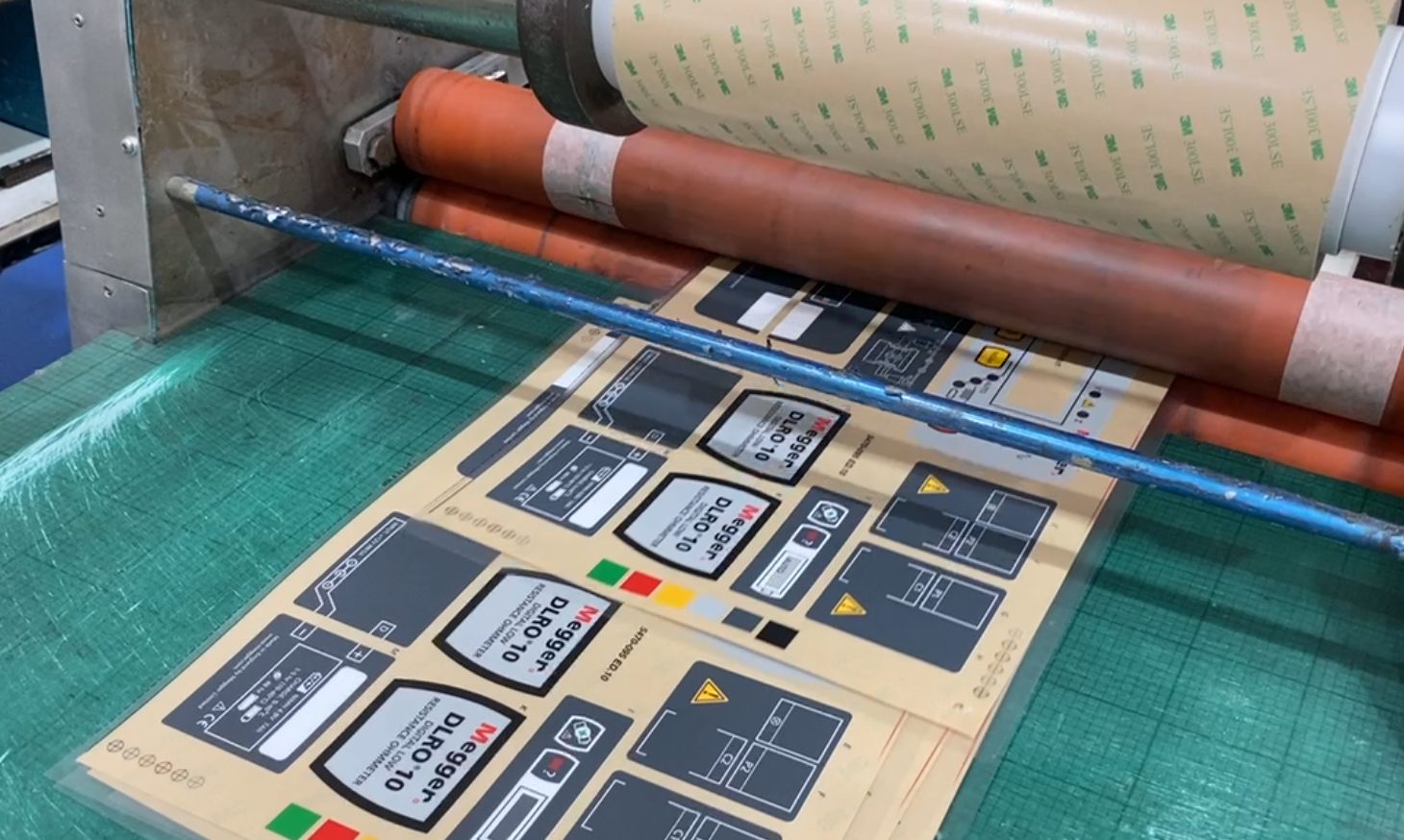

Lamination & Adhesive Application

The final protective layer and bonding solution is tailored for your component’s end-use environment.

- Environmental Protection: Applies high-performance films to resist UV light, abrasion, chemicals, and moisture.

- Bonding Strength: Utilises a wide range of 3M and speciality adhesives for permanent or removable fixing to various surfaces.

- Clean Assembly: Ensures perfect alignment and contamination-free application before delivery, resulting in components ready for immediate use.

Component Assembly and Quality Assurance

The final critical step in our process is delivering a ready-to-use product, achieved through our in-house assembly and quality control capabilities.

- Integrated Component Assembly

- We offer comprehensive services to build complex, multi-layered products by integrating elements like metal back panels, circuitry, display windows, and specialised adhesives.

- This capability transforms individual components into complete, ready-to-install assemblies.

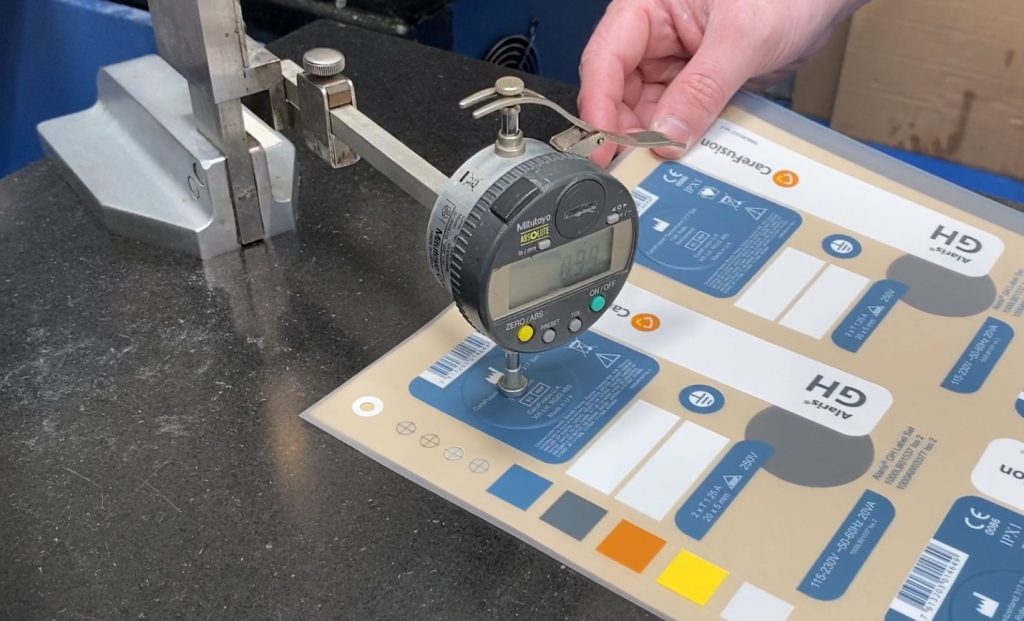

- Rigorous In-House QA & QC

- Every assembled unit undergoes a rigorous Quality Assurance (QA) and Quality Control (QC) regimen before shipment.

- Checks are meticulous, verifying dimensional accuracy, functional performance, and aesthetic perfection to guarantee components meet your exact specifications for immediate, reliable integration.

Why Choose RH Integrated Print Finishing and Secondary Operations?

- End-to-End Control: We manage printing, cutting, and finishing in-house, eliminating hand-offs and ensuring quality and consistency from start to product finish.

- DFM Consultation: Our engineers consult on the best finishing method to optimise your design for maximum performance and cost efficiency.

- ISO 9001:2015 Quality: Every process, from digital cutting to lamination, adheres to our rigorous Quality Management System, guaranteeing reliability.

- Ready-to-Assemble Components: We deliver fully finished components, often with integrated adhesives and protective liners, ready for immediate integration into your product.

Ready to Refine Your Component?

Stop managing multiple suppliers and eliminate the risk of late-stage errors. Trust our expertise to deliver perfectly printed and finished components, ready for your final assembly.